- Product Detail

- Make an inquiry

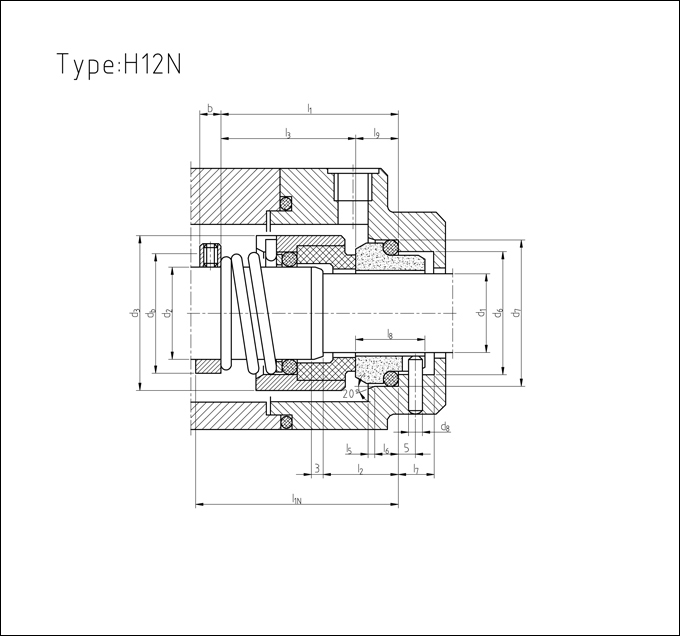

AS-H12N: Burgmann H12N

Features:

Equivalent to Burgmann H12N

For stepped shafts

Single seal

Balanced

Dependent of direction of rotation

Torque transmission via conical spring

Operating range:

Shaft diameter: d1 = 10 ... 80 mm (0.4" ... 3.125")

Pressure: p1 = 25 bar (363 PSI)

Temperature: t = -50 °C ... +220 °C (-58 °F ... +430 °F)

Sliding velocity: vg = 15 m/s (50 ft/s)

Axial movement: ± 1.0 mm

Materials:

Seal face: Carbon graphite antimony impregnated (A)

Seat G9: Silicon carbide (Q1), Special cast CrMo steel (S)

Recommended applications:

Chemical industry

Pulp and paper industry

Water and waste water technology

Low solids content media (H12GN)

Hot water

Chemical standard pumps

Water and sewage pumps

Advantages:

High flexibility due to extended selection of materials

Insensitive to low solids contents

Short Installation length possible (G16)

Economical balanced seal

Seat cooling for hot water applications available (G115)

No damage of the shaft by set screws

SS-H12:

Dimensions, items and descriptions as for H12N, but with seat G16.

Seal face: Carbon graphite antimony impregnated (A)

Seat G16: Silicon carbide (Q1), CrMo cast steel (S), Aluminium oxide (V)

SS-H17GN:

Dimensions, items and descriptions as for H12N, but with shrink-fitted seal face (Q12), item no.1.1.

Temperature: t = -20 °C ... +180 °C (-4 °F ... +356 °F)

Seal face: Silicon carbide (Q12)

Seat G9: Silicon carbide (Q1, Q2), Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B)

SS-H17G:

Dimensions, items and descriptions as for H12N, but with shrink-fitted seal face (Q12) and seat G16.

Temperature: t = -20 °C ... +180 °C (-4 °F ... +356 °F)

Seal face: Silicon carbide (Q12)

Seat G16: Silicon carbide (Q1)

Features:

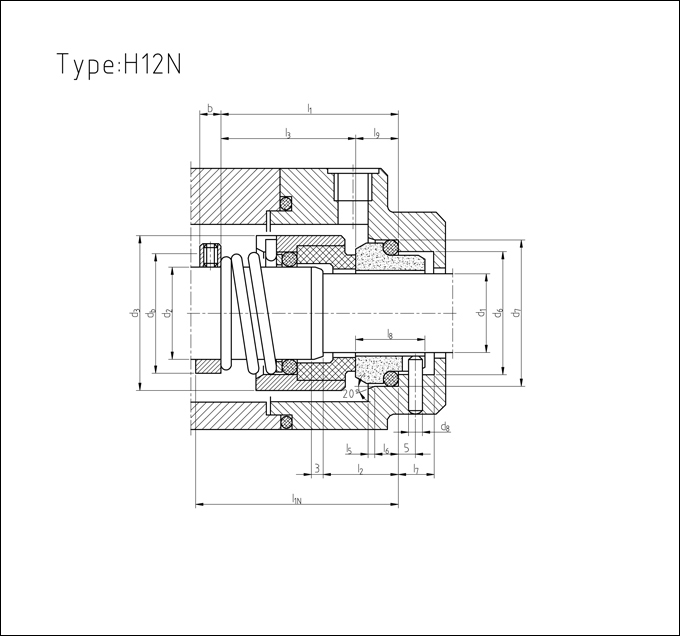

Equivalent to Burgmann H12N

For stepped shafts

Single seal

Balanced

Dependent of direction of rotation

Torque transmission via conical spring

Operating range:

Shaft diameter: d1 = 10 ... 80 mm (0.4" ... 3.125")

Pressure: p1 = 25 bar (363 PSI)

Temperature: t = -50 °C ... +220 °C (-58 °F ... +430 °F)

Sliding velocity: vg = 15 m/s (50 ft/s)

Axial movement: ± 1.0 mm

Materials:

Seal face: Carbon graphite antimony impregnated (A)

Seat G9: Silicon carbide (Q1), Special cast CrMo steel (S)

Recommended applications:

Chemical industry

Pulp and paper industry

Water and waste water technology

Low solids content media (H12GN)

Hot water

Chemical standard pumps

Water and sewage pumps

Advantages:

High flexibility due to extended selection of materials

Insensitive to low solids contents

Short Installation length possible (G16)

Economical balanced seal

Seat cooling for hot water applications available (G115)

No damage of the shaft by set screws

SS-H12:

Dimensions, items and descriptions as for H12N, but with seat G16.

Seal face: Carbon graphite antimony impregnated (A)

Seat G16: Silicon carbide (Q1), CrMo cast steel (S), Aluminium oxide (V)

SS-H17GN:

Dimensions, items and descriptions as for H12N, but with shrink-fitted seal face (Q12), item no.1.1.

Temperature: t = -20 °C ... +180 °C (-4 °F ... +356 °F)

Seal face: Silicon carbide (Q12)

Seat G9: Silicon carbide (Q1, Q2), Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B)

SS-H17G:

Dimensions, items and descriptions as for H12N, but with shrink-fitted seal face (Q12) and seat G16.

Temperature: t = -20 °C ... +180 °C (-4 °F ... +356 °F)

Seal face: Silicon carbide (Q12)

Seat G16: Silicon carbide (Q1)

| AS-H12N Dimensions(mm) | ||||||||||||||||

| l3 | l5 | l6 | l7 | l8 | l9 | l18 | l19 | l39 | l40 | a | b | e | h1 | h2 | k | b*) |

| 25.5 | 1.5 | 4 | 8.5 | 17.5 | 10.0 | - | - | - | - | - | 5 | - | - | - | - | 8.0 |

| 26.5 | 1.5 | 4 | 8.5 | 17.5 | 10.0 | - | - | - | - | - | 5 | - | - | - | - | 8.0 |

| 29.5 | 1.5 | 4 | 8.5 | 17.5 | 10.0 | - | - | - | - | - | 6 | - | - | - | - | 8.0 |

| 31.0 | 1.5 | 4 | 8.5 | 17.5 | 10.0 | - | - | - | - | - | 6 | - | - | - | - | 8.0 |

| 32.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | - | - | - | 6 | - | - | - | - | 8.0 |

| 32.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | - | - | - | 6 | - | - | - | - | 8.0 |

| 32.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | - | - | - | 6 | - | - | - | - | 8.0 |

| 32.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | - | - | - | 6 | - | - | - | - | 8.0 |

| 33.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | - | - | - | 6 | - | - | - | - | 8.0 |

| 35.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | 24 | 8.5 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 35.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | 24.5 | 9.0 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 39.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | 24.5 | 9 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 7.5 |

| 39.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | 24.5 | 9.0 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 7.5 |

| 43.5 | 2.0 | 5 | 9.0 | 19.5 | 11.5 | 15 | 7 | 24.5 | 9.0 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 46.0 | 2.0 | 6 | 9.0 | 22.0 | 14.0 | 16 | 8 | 26 | 11 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 7.5 |

| 48.0 | 2.0 | 6 | 9.0 | 22.0 | 14.0 | 16 | 8 | 26 | 11 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 51.0 | 2.0 | 6 | 9.0 | 22.0 | 14.0 | 16 | 8 | 26 | 11 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 55.0 | 2.0 | 6 | 9.0 | 22.0 | 14.0 | 16 | 8 | 26 | 11 | 24 | 6 | 8 | 6.6 | 22.6 | 9 | (8) |

| 55.0 | 2.0 | 6 | 9.0 | 22.0 | 14.0 | 16 | 8 | 26 | 11 | 24 | 8 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 58.0 | 2.5 | 6 | 9.0 | 23.0 | 15.0 | 17 | 9.5 | 26.5 | 12.5 | 24 | 8 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 60.0 | 2.5 | 6 | 9.0 | 23.0 | 15.0 | 17 | 9.5 | 26.5 | 12.5 | 24 | 8 | 8 | 6.6 | 22.6 | 9 | 8.0 |

| 60.0 | 2.5 | 6 | 9.0 | 23.0 | 15.0 | 17 | 9.5 | 28.5 | 12.5 | 26 | 8 | 8 | 6.6 | 24.6 | 11 | 8.0 |

| 60.0 | 2.5 | 6 | 9.0 | 23.0 | 15.0 | 18 | 10.5 | 28.5 | 12.5 | 26 | 8 | 8 | 6.6 | 24.6 | 11 | 8.0 |

| 60.0 | 2.5 | 6 | 9.0 | 23.0 | 15.0 | 18 | 10.5 | 28.5 | 12.5 | 26 | 8 | 8 | 6.6 | 24.6 | 11 | 8.0 |

| 60.0 | 2.5 | 6 | 9.0 | 23.0 | 15.0 | 18 | 10.5 | 28.5 | 12.5 | 26 | 8 | 8 | 6.6 | 24.6 | 11 | 8.0 |

| 61.0 | 2.5 | 6 | 9.0 | 23.0 | 15.0 | 18 | 10.5 | 28.5 | 12.5 | 26 | 8 | 8 | 6.6 | 24.6 | 11 | 10.0 |

| 63.0 | 2.5 | 7 | 9.0 | 26.0 | 18.0 | 19 | 11.5 | 30.5 | 14.5 | 26 | 8 | 8 | 6.6 | 24.6 | 11 | 10.0 |

| 68.0 | 2.5 | 7 | 9.0 | 26.0 | 18.0 | 19 | 11.5 | 30.5 | 14.5 | 26 | 10 | 8 | 6.6 | 24.6 | 11 | 10.0 |

| 68.0 | 3.0 | 7 | 9.0 | 26.2 | 18.2 | 19 | 11.5 | 30.2 | 14 | 26 | 10 | 8 | 6.6 | 24.6 | 11 | 10.0 |

| *) l1N acc. to EN 12756 is exceeded. | ||||||||||||||||

Browse other products

-

AS-Type 1B: John crane Type 1B balanced mechanical seal

Click to view more>> -

AS-20R/AS-20: John crane Type 20R/20 PTFE wedge seal

Click to view more>> -

AS-Type 6: John crane Type 6 mechanical seal

Click to view more>> -

AS-1527: Eagle 1527(Sealol 1527)

Click to view more>> -

AS-9BT: John crane Type 9BT AES M06 mechanical seal

Click to view more>>