- Product Detail

- Make an inquiry

AS-BT-AR: Burgmann BT-AR mechanical seal

Features:

Replacement of Burgmann BT-AR

Single and dual seal

Short axial installation length

Protection of the shaft along the whole length

Material approvals available

Operating range:

Shaft diameter: d1 = 6 … 60 mm (0.24" ... 2.4")

Pressure: p1* = 6 bar (87 PSI), vacuum … 0.5 bar (7.25 PSI) up to 1 bar (14.5 PSI) with seat locking

Temperature: t* = -20 °C … +120 °C (-4 °F … +248 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

* Depending on medium, size and material

Materials:

Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B, B3), Silicon carbide (Q1,Q6), Tungsten carbide (U)*, PTFE glass fiber reinforced (Y)

Seat: Steatite (X), Aluminium oxide (V, V1),Silicon carbide (Q1, Q6), Tungsten carbide(U)*

Elastomer: NBR (P), EPDM (E), FKM (V),HNBR (X4)

Metal parts: CrNiMo steel (G), CrNi steel (F),1.4057 (F1)*

* Only for SSBT-AR3

Recommended applications:

Water and waste water technology

Food and beverage industry

Water and waste water technology

Building services industry

Food and beverage industry

Domestic and garden pumps

Whirlpool and swimming pool pumps

Dishwasher pumps

Submersible motors/pumps

Water pumps

SS-BT-AR3:

Seal faces made of Tungsten carbide (U). Elastomers and diameter range same as SSBT-AR. The BT-AR3 is the right choice when the seal has to be used in high duty applications or where the seal faces could be damaged by abrasives (waste water).

Features:

Replacement of Burgmann BT-AR

Single and dual seal

Short axial installation length

Protection of the shaft along the whole length

Material approvals available

Operating range:

Shaft diameter: d1 = 6 … 60 mm (0.24" ... 2.4")

Pressure: p1* = 6 bar (87 PSI), vacuum … 0.5 bar (7.25 PSI) up to 1 bar (14.5 PSI) with seat locking

Temperature: t* = -20 °C … +120 °C (-4 °F … +248 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

* Depending on medium, size and material

Materials:

Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B, B3), Silicon carbide (Q1,Q6), Tungsten carbide (U)*, PTFE glass fiber reinforced (Y)

Seat: Steatite (X), Aluminium oxide (V, V1),Silicon carbide (Q1, Q6), Tungsten carbide(U)*

Elastomer: NBR (P), EPDM (E), FKM (V),HNBR (X4)

Metal parts: CrNiMo steel (G), CrNi steel (F),1.4057 (F1)*

* Only for SSBT-AR3

Recommended applications:

Water and waste water technology

Food and beverage industry

Water and waste water technology

Building services industry

Food and beverage industry

Domestic and garden pumps

Whirlpool and swimming pool pumps

Dishwasher pumps

Submersible motors/pumps

Water pumps

SS-BT-AR3:

Seal faces made of Tungsten carbide (U). Elastomers and diameter range same as SSBT-AR. The BT-AR3 is the right choice when the seal has to be used in high duty applications or where the seal faces could be damaged by abrasives (waste water).

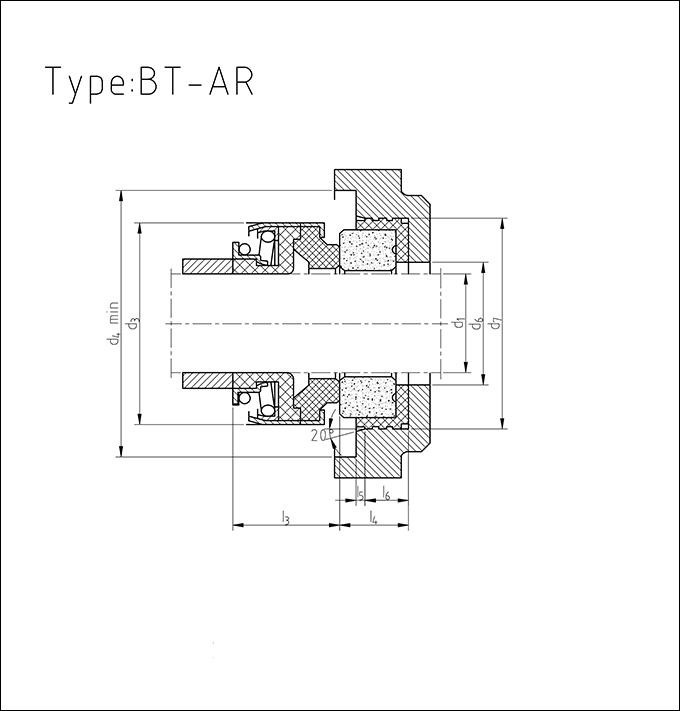

| AS-BT-AR Dimensions(mm) | |||||||||

| d1 | d3 | d4 | d6 | d7 | l3 | tol1 | l4 | l5 | l6 |

| 6 | 18 | 23 | 8 | 22 | 8 | +0.5/0 | 4 | 0.5 | 3.5 |

| 8S | 20 | 23 | 10 | 22 | 11 | +0.5/0 | 4 | 0.5 | 3.5 |

| 8 | 24 | 27 | 10 | 26 | 11 | +0.5/0 | 8 | 1 | 6 * |

| 3/8" | 24 | 24 | 12 | 25.4 | 11 | +0.5/0 | 5.5 | 0.5 | 4.5 |

| 3/8" | 24 | 24 | 12 | 25.4 | 11 | +0.5/0 | 7.5 | 1 | 5.5 |

| 10 | 24 | 27 | 12 | 26 | 11 | +0.5/0 | 8 | 1 | 6 * |

| 11 | 24 | 27 | 13 | 26 | 11 | +0.5/0 | 8 | 1 | 6 * |

| 12 | 24 | 27 | 14 | 26 | 11 | +0.5/0 | 8 | 1 | 6 * |

| 12 | 24 | 27 | 14 | 26 | 12.8 | +0.7/0 | 8 | 1 | 6 * |

| 1/2" | 24 | 24 | 15 | 25.4 | 12.8 | +0.7/0 | 7.5 | 1 | 5.5 |

| 13 | 24 | 27 | 15 | 26 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 14S | 28 | 30 | 18 | 28.5 | 12.8 | +0.7/0 | 7.5 | 1 | 5.5 |

| 14L | 28 | 30 | 18 | 28.5 | 15.3 | ± 0.8 | 7.5 | 1 | 5.5 |

| 14 | 32 | 35 | 16 | 29.5 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 15 | 32 | 35 | 17 | 29.5 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 16R | 32 | 35 | 18 | 29.5 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 16 | 39 | 43 | 18 | 38 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 16 | 39 | 43 | 18 | 42 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 17 | 39 | 43 | 19 | 42 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 18 | 39 | 43 | 20 | 42 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 19 | 39 | 43 | 21 | 42 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 20 | 39 | 43 | 22 | 42 | 12.8 | +0.7/0 | 8 | 1 | 6 |

| 20S | 42 | 47 | 22 | 45 | 12.8 | +0.7/0 | 10 | 1 | 8 |

| 22 | 42 | 47 | 24 | 45 | 12.8 | +0.7/0 | 10 | 1 | 8 |

| 23 | 47 | 52 | 25 | 50 | 13.5 | +1/0 | 10 | 1 | 8 |

| 24 | 47 | 52 | 26 | 50 | 13.5 | +1/0 | 10 | 1 | 8 |

| 25R | 42 | 52 | 27 | 50 | 13.5 | +1/0 | 10 | 1 | 8 |

| 25 | 47 | 52 | 27 | 50 | 13.5 | +1/0 | 10 | 1 | 8 |

| 26 | 47 | 52 | 29 | 50 | 13.5 | +1/0 | 10 | 1 | 8 |

| 27 | 47 | 52 | 30 | 50 | 13.5 | +1/0 | 10 | 1 | 8 |

| 28 | 54 | 60 | 31 | 57 | 15 | +1/0 | 10 | 1 | 8 |

| 30 | 54 | 60 | 33 | 57 | 15 | +1/0 | 10 | 1 | 8 |

| 32 | 54 | 60 | 35 | 57 | 15 | +1/0 | 10 | 1 | 8 |

| 35 | 60 | 70 | 38 | 63 | 16 | +1/0 | 10 | 1 | 8 |

| 38 | 65 | 75 | 41 | 68 | 18 | +1/0 | 12 | 2 | 9 |

| 40 | 65 | 75 | 43 | 68 | 18 | +1/0 | 12 | 2 | 9 |

| 45 | 70 | 80 | 48 | 73 | 20 | +1/0 | 12 | 2 | 9 |

| 50 | 85 | 95 | 53 | 88 | 23 | +1/0 | 15 | 2 | 12 |

| 60 | 105 | 115 | 63 | 110 | 30 | +1/0 | 15 | 2 | 12 |

| * Alternative seat l4 = 5.5, l5 = 0.5, l6 = 4.5 | |||||||||

Browse other products

-

AS-Type 6: John crane Type 6 mechanical seal

Click to view more>> -

AS-20R/AS-20: John crane Type 20R/20 PTFE wedge seal

Click to view more>> -

AS-1527: Eagle 1527(Sealol 1527)

Click to view more>> -

AS-9BT: John crane Type 9BT AES M06 mechanical seal

Click to view more>> -

AS-Type 1B: John crane Type 1B balanced mechanical seal

Click to view more>>