- Product Detail

- Make an inquiry

AS-MBS100

Features

Equivalent MBS100

For unstepped shafts

Rotating bellows

Single Seal

Balanced

Independent of direction of rotation

Operating range

Shaft diameter: d1 = 20 … 100 mm (0.75" … 4")

Pressure: p1 = … 25 (16*) bar 363 (232*) PSI

Temperature: t = -40 °C … +220 (160*) °C (-40 °F … 428 (320*)) °F

Sliding velocity: vg = 20 m/s (66 ft/s)

* Operating limits for material combination Q1/Q1

Materials

Seal face: Silicon carbide (Q12), Carbon graphite (A)

Seat: Silicon carbide (Q1)

Bellows: Inconel® 625 (T3)

Secondary seals: FKM (V)

Metal parts: Duplex (G1)

Recommended applications

Process industry

Refining technology

Power plant technology

Chemical industry

Hot media

Cold media

Highly viscous media

Pumps

Special rotating equipment

Features

Equivalent MBS100

For unstepped shafts

Rotating bellows

Single Seal

Balanced

Independent of direction of rotation

Operating range

Shaft diameter: d1 = 20 … 100 mm (0.75" … 4")

Pressure: p1 = … 25 (16*) bar 363 (232*) PSI

Temperature: t = -40 °C … +220 (160*) °C (-40 °F … 428 (320*)) °F

Sliding velocity: vg = 20 m/s (66 ft/s)

* Operating limits for material combination Q1/Q1

Materials

Seal face: Silicon carbide (Q12), Carbon graphite (A)

Seat: Silicon carbide (Q1)

Bellows: Inconel® 625 (T3)

Secondary seals: FKM (V)

Metal parts: Duplex (G1)

Recommended applications

Process industry

Refining technology

Power plant technology

Chemical industry

Hot media

Cold media

Highly viscous media

Pumps

Special rotating equipment

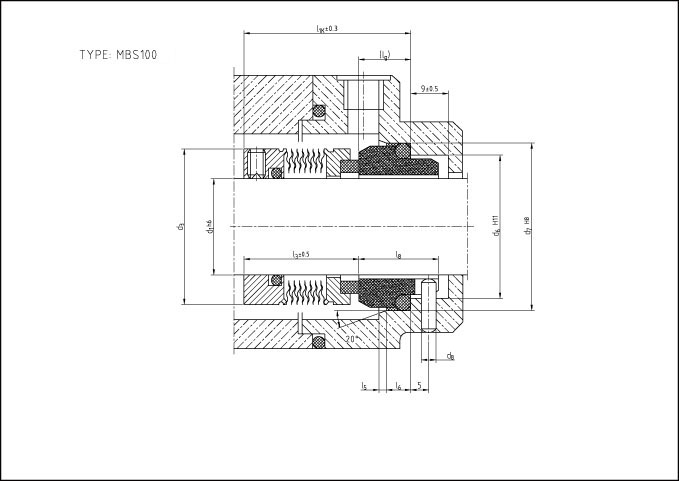

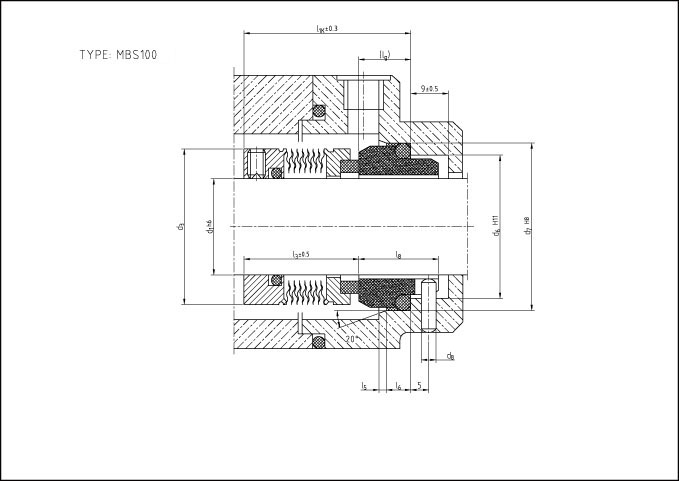

| AS-MBS100 Dimentions(mm) | ||||||||||

| d1 | d3 | d6 | d7 | d8 | l1k | l3 | l5 | l6 | l8 | l9 |

| 20 | 33.3 | 29 | 35 | 3 | 37.5 | 30.5 | 2.0 | 5 | 15.0 | 7.0 |

| 22 | 36.5 | 31 | 37 | 3 | 37.5 | 30.5 | 2.0 | 5 | 15.0 | 7.0 |

| 24 | 39.0 | 33 | 39 | 3 | 40.0 | 28.5 | 2.0 | 5 | 19.5 | 11.5 |

| 25 | 39.0 | 34 | 40 | 3 | 40.0 | 28.5 | 2.0 | 5 | 19.5 | 11.5 |

| 28 | 42.0 | 37 | 43 | 3 | 42.5 | 31.0 | 2.0 | 5 | 19.5 | 11.5 |

| 30 | 44.0 | 39 | 45 | 3 | 42.5 | 31.0 | 2.0 | 5 | 19.5 | 11.5 |

| 32 | 46.0 | 42 | 48 | 3 | 42.5 | 31.0 | 2.0 | 5 | 19.5 | 11.5 |

| 33 | 47.0 | 42 | 48 | 3 | 42.5 | 31.0 | 2.0 | 5 | 19.5 | 11.5 |

| 35 | 49.2 | 44 | 50 | 3 | 42.5 | 31.0 | 2.0 | 5 | 19.5 | 11.5 |

| 38 | 52.4 | 49 | 56 | 4 | 45.0 | 31.0 | 2.0 | 6 | 22.0 | 14.0 |

| 40 | 55.6 | 51 | 58 | 4 | 45.0 | 31.0 | 2.0 | 6 | 22.0 | 14.0 |

| 43 | 58.7 | 54 | 61 | 4 | 45.0 | 31.0 | 2.0 | 6 | 22.0 | 14.0 |

| 45 | 58.7 | 56 | 63 | 4 | 45.0 | 31.0 | 2.0 | 6 | 22.0 | 14.0 |

| 48 | 61.9 | 59 | 66 | 4 | 45.0 | 31.0 | 2.0 | 6 | 22.0 | 14.0 |

| 50 | 65.1 | 62 | 70 | 4 | 47.5 | 32.5 | 2.5 | 6 | 23.0 | 15.0 |

| 53 | 68.3 | 65 | 73 | 4 | 47.5 | 32.5 | 2.5 | 6 | 23.0 | 15.0 |

| 55 | 69.7 | 67 | 75 | 4 | 47.5 | 32.5 | 2.5 | 6 | 23.0 | 15.0 |

| 58 | 74.6 | 70 | 78 | 4 | 52.5 | 37.5 | 2.5 | 6 | 23.0 | 15.0 |

| 60 | 74.6 | 72 | 80 | 4 | 52.5 | 37.5 | 2.5 | 6 | 23.0 | 15.0 |

| 65 | 84.1 | 77 | 85 | 4 | 52.5 | 37.5 | 2.5 | 6 | 23.0 | 15.0 |

| 70 | 87.3 | 83 | 92 | 4 | 60.0 | 42.0 | 2.5 | 7 | 26.0 | 18.0 |

| 75 | 95.3 | 88 | 97 | 4 | 60.0 | 42.0 | 2.5 | 7 | 26.0 | 18.0 |

| 80 | 98.4 | 95 | 105 | 4 | 60.0 | 41.8 | 3.0 | 7 | 26.2 | 18.2 |

| 85 | 104.8 | 100 | 110 | 4 | 60.0 | 41.8 | 3.0 | 7 | 26.2 | 18.2 |

| 90 | 108.0 | 105 | 115 | 4 | 65.0 | 46.8 | 3.0 | 7 | 26.2 | 18.2 |

| 95 | 114.3 | 110 | 120 | 4 | 65.0 | 47.8 | 3.0 | 7 | 25.2 | 17.2 |

| 100 | 120.7 | 115 | 125 | 4 | 65.0 | 47.8 | 3.0 | 7 | 25.2 | 17.2 |

Browse other products

-

AS-Type 609: John crane Type 609 replacement

Click to view more>> -

AS-Type 606: John crane Type 606 replacement

Click to view more>> -

AS-MFL65: Burgmann MFL65 replacement

Click to view more>> -

AS-MFLCT: Burgmann MFLCT replacement

Click to view more>> -

AS-MBS100: Burgmann MBS100 replacement

Click to view more>>